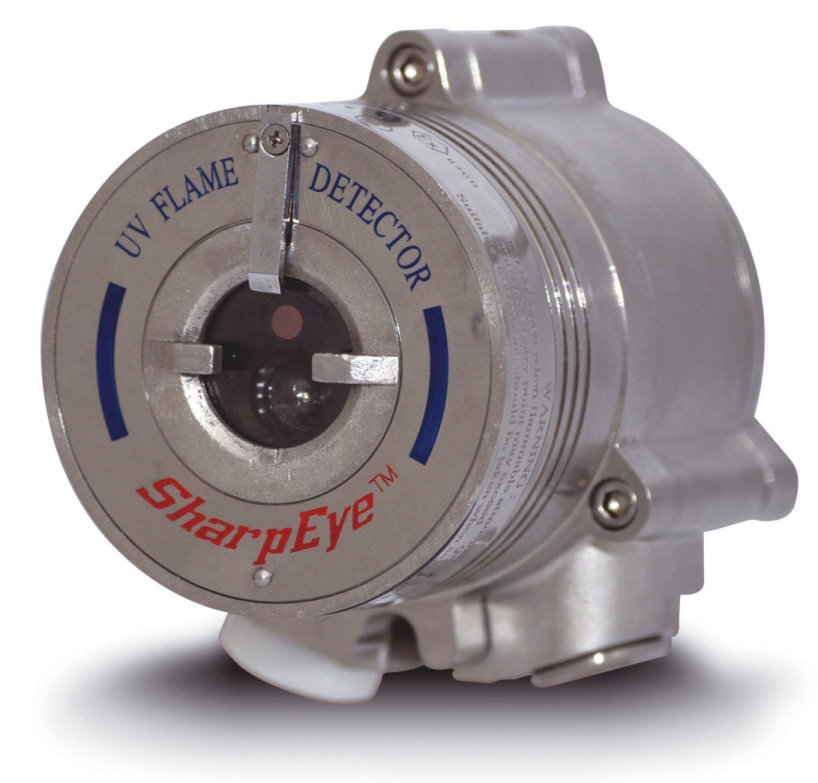

UV Flame Detector 40-40U

UV Flame Detector Explosion Proof enclosure 40/40U SharpEye Spectrex

40/40U - UV Flame Detector - Explosion Proof enclosure SharpEye Spectrex

The new 40/40 UV Flame Detector detects hydrocarbon-based fuel and gas fires, invisible hydrogen flames, and fires from hydrides, ammonia, silane and other organics. The 40/40U-UB is the most durable and weather resistant UV flame detector currently on the market. Its new features include a heated window, to eliminate condensation and icing; HART capabilities, for digital communications; lower power requirements; and a compact, lighter design.

Due to increased reliability, the 40/40 Series warranty period has been extended to 5 years and is SIL2 (TUV) approved to IEC 61508.

The model 40/40UB includes a Built-in-Test (BIT) feature, whereas the 40/40U model does not.

Note: This type of detector should not be exposed to UV radiation sources such as welding, sparks, and electric arcs as it will cause false alarms.

Standard enclosure : Aluminium (Stainless Steel enclosure in option)

FEATURES & BENEFITS

- UV spectrum design

- 3 seconds response

- Automatic and Manual Built-In-Test (BIT) - to assure continued reliable operation

- Heated window - for operation in harsh weather conditions (snow, ice, condensation)

- Multiple output options for maximum flexibility and compatibility: - Relays (3) for Alarm, Fault and Auxiliary - 0-20mA (stepped) - HART Protocol for maintenance and asset management - RS-485, Modbus Compatible

- High Reliability - MTBF - minimum 150,000 hours

- Approved to Safety Integrity Level 2 (SIL2 - TUV) Model 40/40UB only

- 5-Year Warranty

- User Programmable via HART or RS-485

- Ex approved for Zone 1 hazardous area location : - ATEX - IECEx - FM/FMC - CSA

- 3rd party Performance Tested : - EN54-10 (LPCB) - FM3260 (FM)

APPLICATIONS

- Chemical plants

- Petrochemicals plants

- Power Generation facilities

- Pharmaceutical Industry

- Printing Industry

- Warehouses

- Automotive Industry

- Aerospace

- Explosives & Munitions

- Waste Disposal facilities

- Paint and solvent processes

GENERAL SPECIFICATIONS

- Spectral Response : UV 0.185-0.260 um

- Detection Range : n-Heptane 15m, Ethanol 95% 11m, LPG 12m, Gasoline 15m, Methanol 11m, Polypropylene Pellets 5m, Diesel Fuel 11m, IPA (Isopropyl Alcohol) 11m, Office Paper 6m, JP5 11m, Hydrogen 10m, Kerosene 11m, Methane 12m

- Response Time Typically : 3 seconds

- Adjustable Time Delay : Up to 30 seconds

- Sensitivity Ranges : 0.1m2 n-heptane pan fire from 15m

- Field of View : Horizontal 100©; Vertical 95©

- Built-in-Test (BIT) : Automatic (and Manual)

- Temperature Range : Operating: -55°C to +75°C, Option: -55°C to +85°C, Storage: -55°C to +85°C

- Humidity : Up to 95% non-condensing (withstands up to 100% RH for short periods)

- Heated Optics : To eliminate condensation and icing on the window

ELECTRICAL SPECIFICATIONS

- Operating Voltage : 24 VDC nominal (18-32 VDC)

- Power Consumption : Standby: Max. 90mA (110mA with heated window), Alarm: Max. 130mA (160mA with heated window)

- Cable Entries : 2 x 3/4" - 14NPT conduits or 2 x M25 x 1.5 mm ISO

- Wiring : 12 - 22AWG (2.5mm2 - 0.3mm2)

- Electrical Input Protection : According to MIL-STD-1275B

- Electromagnetic Compatibility : EMI/RFI protected to EN61326-3 and EN61000-6-3

- Electrical Interface : The detector includes twelve (12) terminals with five (5) wiring options (factory set)

OUTPUTS

- Relays : Alarm, Fault and Auxiliary, SPST volt-free contacts rated 5A at 30 VDC or 250 VAC.

- 0-20mA (stepped) : Sink (source option) configuration, Fault: 0 +1mA, Warning: 16mA © 5%, BIT Fault: 2mA © 10%, Alarm: 20mA © 5%, Normal: 4mA © 10%, Resistance Loop: 100-600 e

- HART Protocol : Optional HART communications on the 0-20mA analog current (FSK) - used for maintenance, configuration changes and asset management, available in mA source output wiring options

- RS-485 : RS-485 Modbus compatible communication link that can be used in computer controlled installations

MECHANICAL SPECIFICATIONS

- Materials : - Stainless Steel 316L with electro polish finish, Enclosure options - Heavy duty copper free aluminum (less than 1%), red epoxy enamel finish

- Mounting : Stainless Steel 316L with electro polish finish

- Dimensions Detector : 101.6 x 117 x 157 mm

- Weight : Detector : 2.8 kg, Tilt mount : 1.0 kg, Detector, aluminum : 1.3 kg

- Environmental Standards : Meets MIL-STD-810C for Humidity, Salt & Fog, Vibration, Mechanical Shock, High Temp, Low Temp

- Water and Dust I: P66 and IP67 per EN60529, NEMA 250 6P

APPROVALS

- Hazardous Area : ATEX and IECEx Ex II 2 GD, Ex de IIC T5 (-55°C to +75°C) Ex de IIC T4 (-55°C to +85°C), Ex tD A21 IP66/X7 T 95°C Ex tD A21 IP66/X7 T 105°C, FM/FMC/CSA Class I Div. 1, Groups B, C & D, Class II/III Div. 1, Groups E, F & G

- Performance : EN54-10 (LPCB), FM-3260 (FM)

- Reliability : IEC61508 - SIL2 (TUV) - model 40/40UB only

English (UK)

English (UK)  Français (FR)

Français (FR)